Models

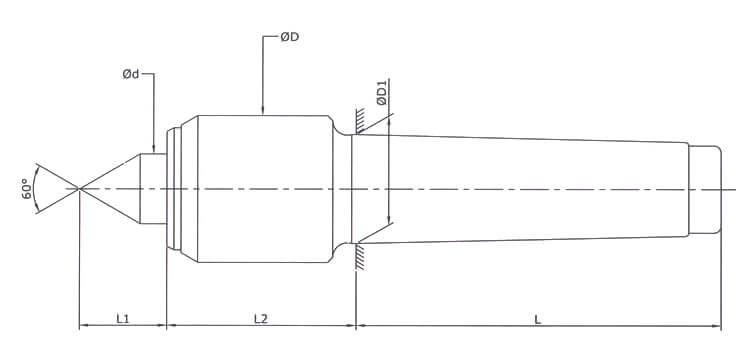

| Part No. | Shank Taper | Point Style | Ød mm | ØD mm | ØD1 mm | L1 mm | L2 mm | L mm | Max.Job Wt. Kg. | Conc. Error mm | Max. RPM |

|---|---|---|---|---|---|---|---|---|---|---|---|

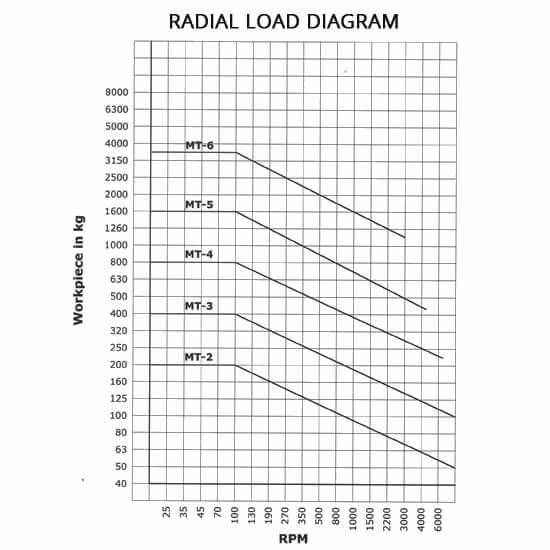

| HSC MT2 CNC MD SCS | MT-2 | Stub Point | 15 | 34 | 17.780 | 19 | 48.5 | 64.0 | 150 | 0.008 | 6300 |

| HSC MT3 CNC MD SCS | MT-3 | Stub Point | 15 | 34 | 23.825 | 19 | 48.5 | 81.0 | 375 | 0.008 | 6300 |

| HSC MT4 CNC MD SCS | MT-4 | Stub Point | 20 | 42 | 31.267 | 25 | 56.0 | 102.5 | 600 | 0.008 | 5600 |

| HSC MT5 CNC MD SCS | MT-5 | Stub Point | 32 | 68 | 44.399 | 41 | 78.0 | 129.5 | 1500 | 0.015 | 3300 |