Models

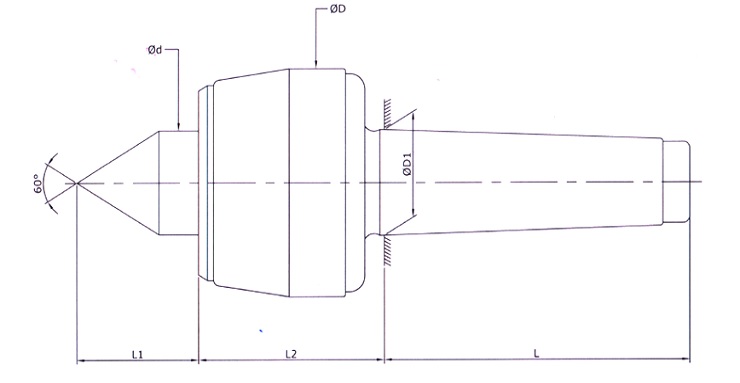

| Part No. | Shank Taper | Point Style | Ød mm | ØD mm | ØD1 mm | L1 mm | L2 mm | L mm | Max. Job Wt. Kg. | Conc. Error mm | Max. RPM |

|---|---|---|---|---|---|---|---|---|---|---|---|

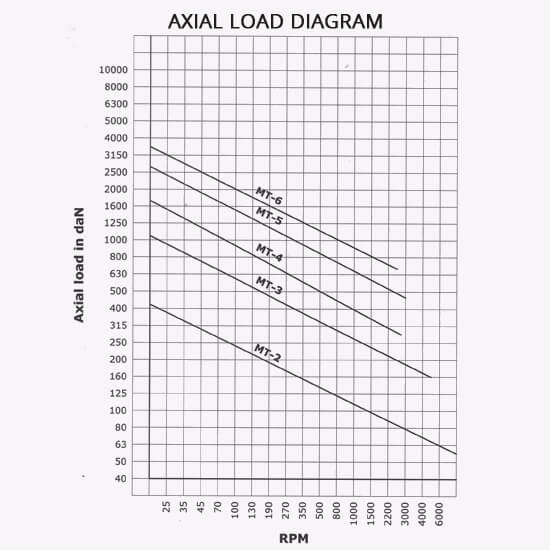

| HSC MT2 CNC HDR S | MT-2 | Stub Point | 20 | 46 | 17.780 | 25.0 | 50.5 | 64.0 | 150 | 0.008 | 6300 |

| HSC MT3 CNC HDR S | MT-3 | Stub Point | 28 | 62 | 23.825 | 34.0 | 64.5 | 81.0 | 375 | 0.008 | 4500 |

| HSC MT4 CNC HDR S | MT-4 | Stub Point | 32 | 68 | 31.267 | 41.0 | 65.0 | 102.5 | 600 | 0.008 | 3450 |

| HSC MT5 CNC HDR S | MT-5 | Stub Point | 38 | 87 | 44.399 | 51.0 | 83.0 | 129.5 | 1500 | 0.008 | 2700 |

| HSC MT6 CNC HDR S | MT-6 | Stub Point | 50 | 102 | 63.348 | 57.5 | 101.5 | 182 | 2600 | 0.015 | 2300 |